EN

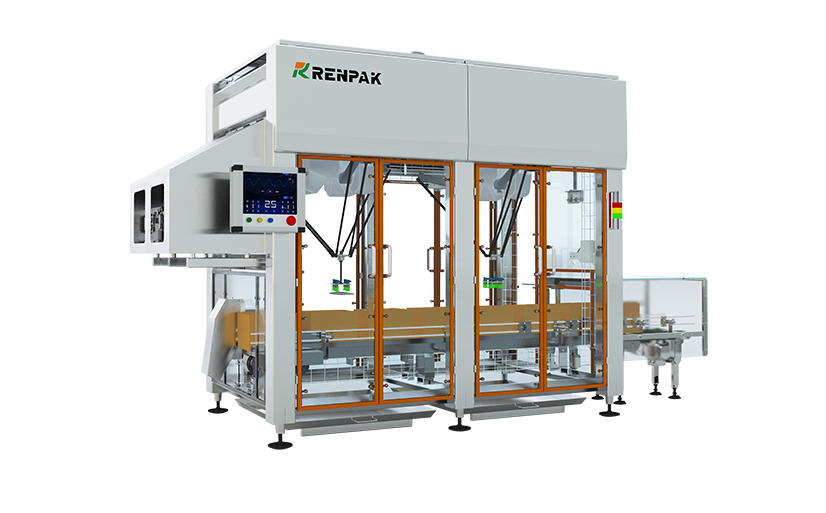

CASE PACKER

ZXZND Case Packer is an automatic packing equipment that uses delta 3 robots to directly pick products from the belt conveyor and place them into the cases. The machine is consisted of feeding conveyor, delta 3 robot, case conveying system and gripper with vacuum system. At the entrance of the machine, the sensor or a camera will detect the position of the products, and then the control system will guide the robot to follow and pick the products on the conveyor, then place the products directly into the erected cases to realize case packing. The robot can handle 1-2 products at a time, and the position of placing is programmable. The process characteristics make this model highly adaptable to various products and and flexible in case packing configuration.

RSC

L(320-400)mm X W(130-300)mm X H(100-260)mm

Up to 15 cases/min

Flexible packaging bag with small piece of material inside

L(100-400)mm X W(100-400)mm X H(1-50)mm

3kg

Up to 200 pieces / min

Sensor or visual guide

Horizontal arrangement, any configuration

L 4400mm X W 1830mm X H2610mm

2000kg

1.The main parameters are the performance based on two robots in series, and the specific parameters will be different according to different project applications.

2.The technical documents approved by Renpak according to specific projects will finally prevail.

Dear user, hello!

Please fill in the following form to obtain product files.Phone

TOP